Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent. They are easily worked, molded, and thermoformed. Because of these properties, polycarbonates find many applications. Polycarbonates do not have a unique resin identification code (RIC) and are identified as “Other”, 7 on the RIC list. Products made from polycarbonate can contain the precursor monomer bisphenol A (BPA).

PTFE is a fluorocarbon solid, as it is a high-molecular-weight compound consisting wholly of carbon and fluorine. PTFE is hydrophobic: neither water nor water-containing substances wet PTFE, as fluorocarbons demonstrate mitigated London dispersion forces due to the high electronegativity of fluorine. PTFE has one of the lowest coefficients of friction of any solid.

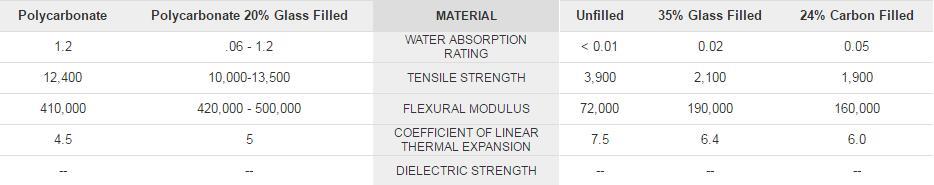

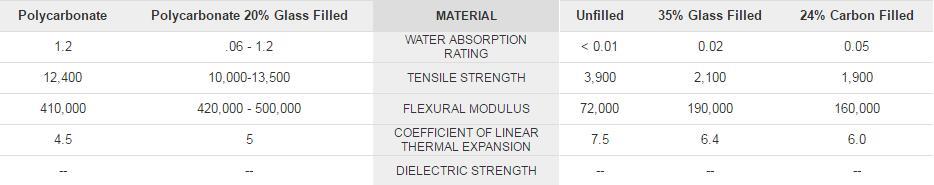

Comparison of Polycarbonate and polymer PTFE/FEP Property Values

Material Applications

Polycarbonates (PC) ![]() ower distribution (covers and housings);Connectors;Seals and gaskets;Food processing machinery components;Electrical household appliances;Wheels & rollers;Battery boxes.

ower distribution (covers and housings);Connectors;Seals and gaskets;Food processing machinery components;Electrical household appliances;Wheels & rollers;Battery boxes.

Polymer PTFE/FEP:Cabling solutions;Non lubricated bearings;O-rings;Seals;Capacitors;Semiconductor manufacturing;High temperature electrical parts;Gaskets;Valve components.

Material Properties

Polycarbonates (PC):Easily machined;Excellent creep;Glass-filled grades available;High impact strength;FDA compliant grades available;Enhanced bearing & wear grades available.

Polymer PTFE/FEP:Excellent dielectric properties;Inertness to most chemicals;High heat and chemical resistance;Very low coeffiecient of friction;Excellent radiation resistance;Zero moisture absorption;Relatively insensitive to power frequency;Machinability.

Post time: Dec-14-2018