The raw materials of PTFE gaskets have their own available temperature and working pressure range values. Most gaskets cannot be used for high temperature and high working pressure. When selecting the gasket, it should first be adopted according to the gasket’s working temperature, actual operating pressure, and Pr value.

The raw materials of PTFE gaskets have their own available temperature and working pressure range values. Most gaskets cannot be used for high temperature and high working pressure. When selecting the gasket, it should first be adopted according to the gasket’s working temperature, actual operating pressure, and Pr value.

The raw materials of PTFE gaskets must be resistant to chemical corrosion and physical corrosion. Appropriate gaskets should be used according to the actual operating substance types and corrosion characteristics, and then the hydrodynamic corrosion resistance of the gasket raw materials should be considered. The hydrodynamic corrosion resistance is generally indicated by the increase in thickness and net weight of the gasket material after liquid infiltration. For gaskets that touch non-plastic materials, maintaining a proper thickness increase rate of gasket materials is beneficial to the improvement of sealing performance under the premise of ensuring other properties.

The creep relaxation rate of the PTFE gasket is the key parameter for the qualitative analysis of the performance of the gasket material. It reflects the ability of the gasket material to resist stress relaxation and creep deformation. general. The smaller the creep relaxation ratio, the greater the internal stress during work. The better the sealing performance is for non-asbestos gaskets. Creep relaxation is the key reason for the leakage of the looper flange during the working cycle. It plays a decision-making effect on the service life of the connection. The shrinkage performance of PTFE gasket reflects the ductility or plastic deformation of the gasket under the effect of moment load. To make up for the various shortcomings of the flange surface. In turn, the performance of preventing leakage.

Generally speaking, most of the shrinking performance of non-asbestos gaskets can be considered for sealing regulations. Compared with the expansion, the resilience performance is the most important index value. The resilience performance refers to the ductility compensation of the gasket, which can follow the separation of the flange due to temperature or mechanical equipment load to maintain the seal. The performance of the PTFE gasket is the main comprehensive performance of the quality of the gasket, and the leakage rate is a visual index value. Based on the leak rate index value, the sealing ability of the gasket can be quantitatively analyzed and compared. The leakage rate is the basic parameter that should be considered when selecting gaskets.

4 Things Need to Concern when Installing PTFE Gaskets

1. The sealing line or raised surface of the PTFE gasket seal must not be damaged. The PTFE gasket seal in the plan view can use the left and right inner holes. The sealing performance of the PTFE gasket seal of the hydraulic machine is mainly based on the shaft or hole. A well-matched lip line must be very careful in the entire process of installation, transportation, and storage. This part is made of soft and resilient high-purity graphite, chemical fiber, rubber, and plastic that is resistant to corrosion, high temperature and aging. Insulation board and other such vulnerable materials are composed of materials, so once damaged, it will cause great hidden danger to the sealing part.

2. When installing PTFE gasket seals, we must be very cautious, and the insertion process must be gradually carried out. During the whole installation process, do not force the installation with too large a posture, which will make everyone’s PTFE gasket seals. The initial prefabricated component structure was destroyed.

3. The installation of PTFE gasket seals must comply with symmetry and balance. When installing, place the PTFE gasket seal on the position of the stuck lip surface (or reasonable raised surface) to avoid system software work During the whole process, due to the change (for example, increase) of its working conditions, the failure caused by micro-leakage occurred. It is necessary to continuously observe and do a good job in the next step of the PTFE gasket seal.

4. The PTFE gasket has comprehensive performance, heat resistance, corrosion resistance, non-stick, self-lubricating, electrochemical performance, and very low friction resistance.

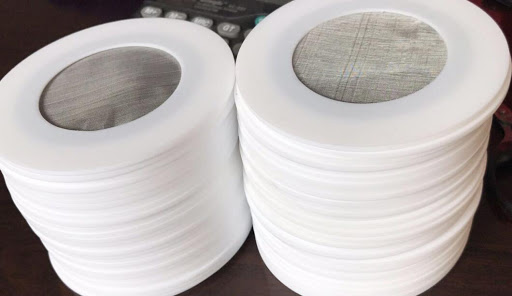

As rubber products, modified PTFE gaskets can be made into polytetrafluoroethylene pipes, rods, belts, plates, plastic films, etc. They are generally used in corrosion-resistant pipelines, utensils, pumps, valves and their Control radar detection, high-frequency communication equipment, wireless communication equipment, etc.

All fillers that can bear the calcination temperature of PTFE are added to the modified tetrafluoroethylene gasket. The types of fillers include glass fiber, metal materials, metalized metal oxides, high-purity graphite, molybdenum disulfide, carbon fiber soft, Polyimide film, etc., its mechanical equipment performance can be greatly improved. In addition, other properties of PTFE can be maintained, and the wear resistance and PV value can be increased by 1000 times.

Post time: Aug-17-2020